Technology to Implant Codes

Coded Imagery has developed and patented the technology to implant invisible security marks below the surface of materials such as glass, plastics, ceramics and even, diamonds. While these security marks can be readily verified, they cannot be counterfeited due to the unique method with which they are created. The encoded text or image is precisely formed below the hard surface of the material using special processes such as laser micro-ablation.

Coded Imagery Equipment, Features & Competitive Advantage

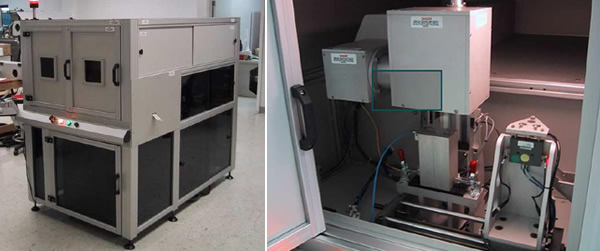

Proprietary Equipment

Writer: Laser-enabled Micro-Ablation

Transforms an encoded text or photographic information into nanometer-size micro-structure marks under the surface of transparent or translucent substrates such as plastic cards and glass vials.

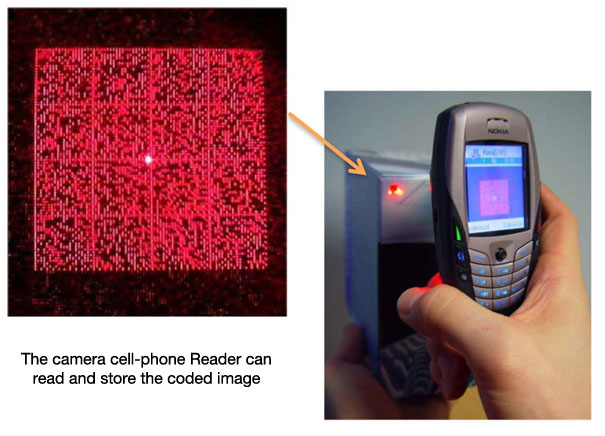

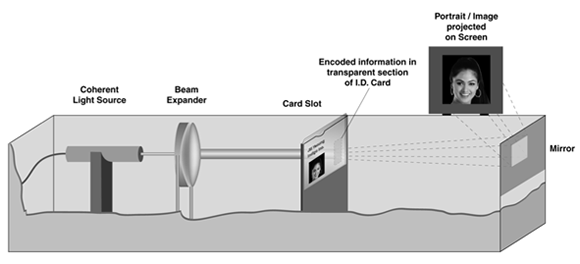

Reader: Handheld Reading/Recording Device

Reveals, upon appropriate interrogation, the encoded information from these covert marks, in the form of projected or digitally-captured images. Platforms that utilize, sophisticated, machine-readable and/or encryption-based systems for high-security applications are envisioned as next generation product applications. The strength of the technology lies in its ability to record encoded, serialized or mass-customized information — in the form of secure, tamper-proof, forgery-resistant micro-structures within conventional substrates such as plastics and glass, and to allow sensitive private biometric or identification information to be placed in a public domain without breach of security.

The technology can be applied to:

- Deter Identity Theft

- Discourage Counterfeiting of Goods and Forgery of Documents

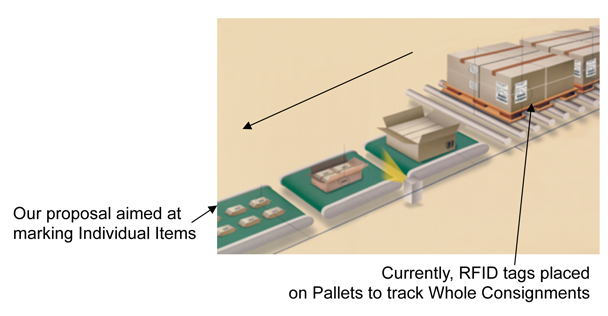

- Detect and delimit Product Diversion and Gray Market Proliferation, through a Track-and-Trace application.

Unique Combination of Features

- The mark is Clear i.e. virtually invisible, no inks or coloration, no superficial labels.

- The mark is Encrypted — not reproducible by known duplication techniques.

- The mark is Protected and Hidden below the Surface of the product, ID card or package.

- The Process enables each Individual mark to be Unique — in the form of text, barcodes, serial/random codes, illustrations, logos, tonal images and photographs.

- The Process is Versatile — to mark Glass, Crystal, Plastics, Ceramics & Composites.

- The Readout is Objective and Definitive — either present or absent, no gray areas.

- The Reader enables Direct Human Viewing as well as Machine Vision.

- The Reader enables Saving and Retrieving of images from a secure database/archive.

Our Clear-and-Secure marks are impossible to replicate using currently available alternative technologies such as reprography, printing, embossing, etching or marking.

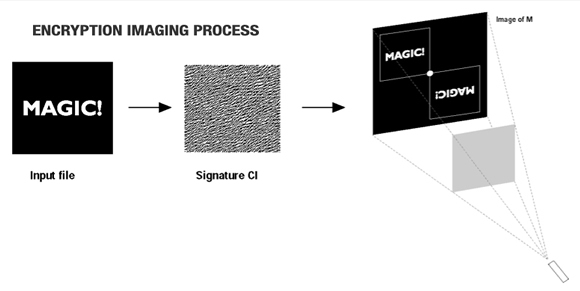

The "Encryption Imaging" Advantage

Coded Imagery's Coded Technology cannot be counterfeited for the following reasons:

- The mark cannot be seen by the naked eye.

- The mark is imprinted below the surface, so it cannot be modified or tampered with.

- The unique coded process and equipment are impossible to decrypt or reverse-engineer.

- Producing the mark requires a proprietary Coded Imagery coded machine.

- Coded Technology uses sophisticated levels of encryption to produce the mark.

- Any manufacturer can use a handheld laser device to quickly and confidently determine whether a product has been pilfered or counterfeited.

The Authentication Industry

The Need to Proactively Combat Counterfeiting

- The global counterfeit industry generates an estimated $670 billion annually.

- Annual earnings from the sale of counterfeit and substandard medicines is over $32 billion worldwide.

- The global anti-counterfeit packaging market is expected to be worth $79.3 billion by 2014, growing at an estimated CAGR of 8.6% from 2009 to 2014

- North America is the largest region in the anti-counterfeit market and is expected to reach $49 billion by 2014, accounting for nearly 62% of the revenues, and growing at a CAGR of 6.8%.

- Asia is next in terms of market size, and is expected to reach $14 billion by 2014 with a CAGR as high as 19.7%.

Holograms… not the perfect foil to counterfeiting

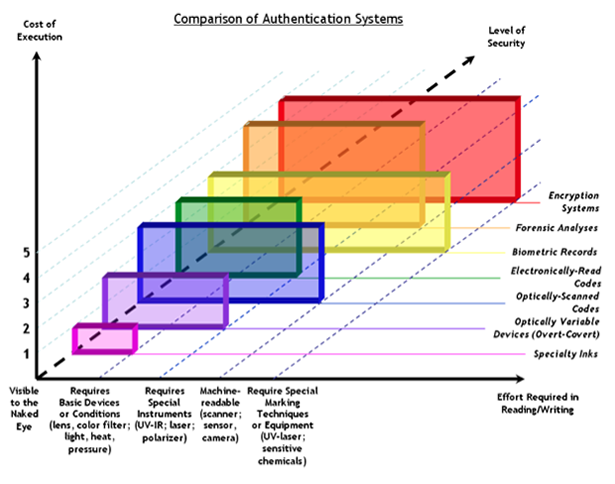

Currently, Authentication Technologies range from specialized printing techniques, special inks, dyes, and fibers, placed on customized paper and film substrates, to holograms and watermarks, to sophisticated molecular/biochemical taggants to electronic codes and secure databases.

The most basic Anti-Counterfeit Devices can be read directly by the naked eye. Most of them require reading instruments. And some of them require specialized knowledge and skill including forensic labs.

Each of the Current Anti-Counterfeiting Devices and Techniques has certain shortcomings:

- They are superficially placed, embossed or printed on the branded item or ID document. Thus they can be 'lifted', duplicated, vandalized, destroyed or removed without a trace.

- They rely on production techniques to that can be re-created, reverse engineered, copied.

- They do batch processing i.e. they do not allow for individual marking of each item with variable/unique data e.g. photograph, random alpha-numeric code, biometric data etc.

- They are expensive at the individual item level. They require masters to be made for each piece of data to be marked.

- They help authenticate the goods after-the-fact. They are not preventative. They require intrusive interrogation as in a forensics lab.

- They may compromise consumer/user privacy or are vulnerable to 'hacking'.

- They are not environment-friendly.